VANE COMPRESSORS

TechnologiesVANE COMPRESSORS

VANE COMPRESSORSVane Compressors

Lubricated Vane Compressors: Robust and Reliable

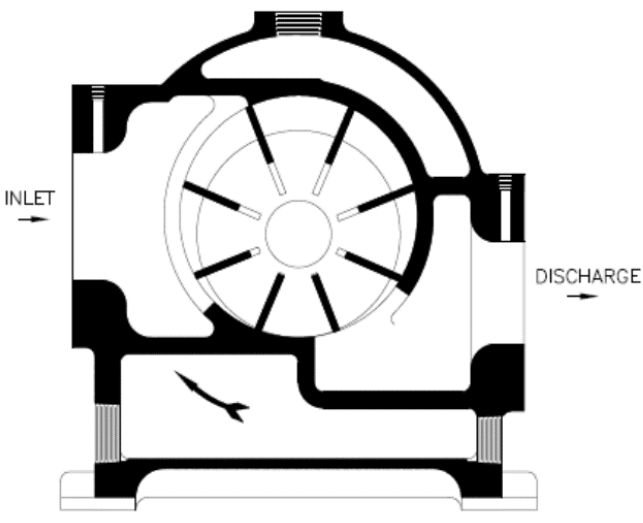

Lubricated sliding vane compressors from RO-FLO are recognized for their ability to handle sour, acid, and wet gases, making them ideal for applications where cost-effectiveness and maintenance are key considerations. These compressors are celebrated for their long service life, with individual units operating for up to 50 years. Maintenance is straightforward, often requiring only one person and can be completed within a single shift. The direct injection lubrication system reduces friction, provides cooling, and carries away debris, ensuring smooth and efficient operation.

- Rotor Eccentrically located.

- Blade / Bore sealed by centrifugal force.

- Rotation reduces cell volume (Positive displacement).

- Power optimized / Port angle.

Features:

- Rotor blades: The durable OEM designed blades are a key component in continuous, reliable operation.

- Shaft seals: Proven high performance single face and dual opposed options available.

- Rotor & Shafts: Constructed from single piece of steel.

- Roller bearings: Custom designed and manufactured with materials for corrosion resistance and proper clearances for broad operating range.

- Seal Rings: Oil buffered seal rings protect the bearings from process contaminants.

- No limit to the amount of H2S allowed in the gas stream.

- 3600+(MSCFD) flowrate.

- 200 Psig maximum allowable working pressure.

- NACE MR1075 compliant casing

Application

Oil & Gas and Petrochemical industry:

- Tank battery vapour recovery unit (VRU)

- Boil-off gas recovery.

- Gas gathering

- Flare gas recovery.

- NGL recovery

- Acid gas treatment.

Green Energy: (BIOGAS)

- Landfill gas collection

- Digester gas collection

- RNG/CNG

- Digester mixing

- Syngas production

Power generation: (NATURAL GAS)

- Gas engine booster

- Gas turbine booster

- Boilers

- Combustor

Power generation: (NATURAL GAS)

- Vacuum chilling

- Ammonia compressor

- Refrigerant compressor

Industries usingAccessories Of AODD & EODD

PartnersPartners who trust

Industrium co