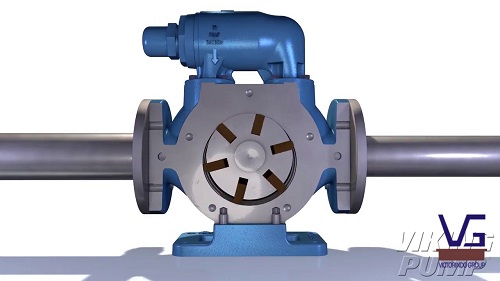

VANE PUMP

TechnologiesVANE PUMP

For over 60 years VIKING pumps has been manufacturing sliding vane pumps to complement their line of rotary positive displacement pump.

VaneVane Pump

The LVP Series™ vane pump is the perfect solution for thin, corrosive industrial liquids, flammable liquids which require corrosion protection and applications where pressures or vacuum requirements exceed other pumps’ capabilities.

Features & Benefits

- Vane pump design offers ANSI or DIN flanges, and IEC or NEMA motor mounts to conform to international standards for enhanced application flexibility

- High pressure and high efficiency with thin liquids 20-minute inline vane replacement reduces scheduled downtime

- Harder components than other vane pumps extend pump life

Materials Of Construction & Configuration Options:

- EXTERNALS (HEAD & CASING): 316 stainless steel

- INTERNALS (ROTOR & SHAFT): 316 stainless steel

- INTERNALS (VANES & PUSH RODS): PEEK

- BUSHINGS: Silicon carbide

- SHAFT SEAL: Component mechanical seal, cartridge mechanical seal, cartridge triple lip seal

Typical Applications:

Common vane pump applications include, but are not limited to:

- Acids & alkalis

- Alcohols & solvents

- Aqueous solutions

- Monomers

- Hexane, pentane

- Refined fuels

- Reactor vessel ingredient metering

- Vacuum vessel service

- Suction lift applications

- Long suction or discharge line applications

Advantages:

- Opposite Porting: For easy in-line mounting

- Seal Chamber: Accommodates the use of component and cartridge seals

- Hardened 316SS Housing with Non-Metallic Pumping Elements: Offer broad chemical compatibility and enhanced application flexibility

- Rated to 200 PSI: Even on the thinnest liquids

- Self-Priming Capabilities: Simplify start-up process

- Sliding Vane Design: Self-adjusts for wear to maintain consistent performance

- Superior Volumetric & Mechanical Efficiency: For low energy consumption

- Internal Relief Valve: Provides over pressure protection

- Gauge Ports: Allow simple addition of local or remote monitoring systems

Industries usingAir Operated Double Diaphragm (AODD)

PartnersPartners who trust

Industrium co