VALVES

TechnologiesVALVES

Flowrox solutions entail more than 45 years of experience in flow and process control and elastomer technology. Flowrox™ valves and pumps are designed for demanding process conditions in a variety of process industries, especially in the mining, minerals processing, metallurgy, construction, energy, environment, and chemical industries.

ValvesFlowrox valves

We provide pinch and slurry knife gate valves for flow control. Flowrox™ pinch valves can be either used for shut-off (also known as isolation) or control. Every Flowrox valve is fit for the most demanding applications in which conventional ones encounter problems with wear due to increased turbulence. When the controlled flow is abrasive, it is a big advantage to have only one, wear-resistant, valve part in contact with the medium. The need for maintenance and spare parts is reduced. We provide tailor-made valves for flow control solutions precisely according to given specifications

ValvesHeavy duty Pinch valves for shut-off and control application

Flowrox PV, PVE and PVE/S heavy duty pinch valves are designed for shut off and control applications involving abrasive or corrosive slurries, powders or granular substances. In the open position, the valve is full bore with no flow restrictions. During closing, two pinch bars squeeze the valve sleeve shut on the center line. Bubble tight shut-off is provided even if solids have built up on the sleeve wall.

Technical Specifications

Series:

PV

PVE

PVE/S

Construction:

Open body

Enclosed body

Enclosed/Sealed body

Size range:

80 - 600 mm / 3 - 24 in

25 - 1000 mm / 1 - 40 in

25 - 800 mm / 1 - 32 in

Pressure range:

0 - 25 bar / 0 - 362 psi

0 - 100 bar / 0 - 1450 psi

0 - 100 bar / 0 - 1450 psi

Temperature range:

-25 - 50 °C / -32 - 122 °F

-25 - 80 °C / -32 - 176 °F

-25 - 80 °C / -32 - 176 °F

ValvesFlowrox™ PVG and PVEG pinch valves Reliable solution to replace diaphragm valves

Flowrox PVG and PVEG pinch valves are robust and cost effective with simple, single-sided closing mechanism. PVG valve has a strong valve body and opening tags in the sleeve as a standard. PVEG valve has a corrosion resistant and light-weight plastic body. Through the reliability and structure, both kinds of valves offer substantial savings based on improved performance, long service lifetime and low total cost of ownership. Flowrox PVG and PVEG valves are ideal for low cycle applications involving abrasion, corrosion and aggressive slurries

Technical Specifications

Series:

PVG

PVEG

Size range:

50 - 250 mm / 2 - 10 in

50 - 150 mm / 2 - 6 in

Pressure range:

0 - 10 bar / 0 - 145 psi

0 - 10 bar / 0 - 145 psi

Temperature range:

0 - 110 °C / 32 - 230 °F

0 - 70 °C / 32 - 158 °F

Benefits Flowrox pinch valves

Improved process efficiency

- 100% tight shut-off even if solids have built upon the sleeve wall. When compressed, any crystallized particles flake off the sleeve surface.

Improved customers' productivity

- Full bore: Ensured free flow of the medium and less pumping energy is required.

Ease of maintenance

- Only the sleeve is in contact with the medium and is the only replaceable part. Can be easily changed on site.

Accurate control

- Improved controllability with conical sleeve results in linear control curve.

Extended service intervals

- High corrosion resistance and flexible sleeve.

Reliable & trouble-free operation

- Extremely wear resistant. 100% tight shut-off even with particles. No jamming or clogging

Long lifetime with low maintenance costs

- Strong metal body, simple closing mechanism and opening tags in the sleeve as a standard.

Simple and low-cost to service

- Only the sleeve is in contact with the medium and is the only replaceable part.

Easy and quick installation

- Face-to-face according to industry standard (EN558 ser 7).

No flow restriction

- Due to full bore structure.

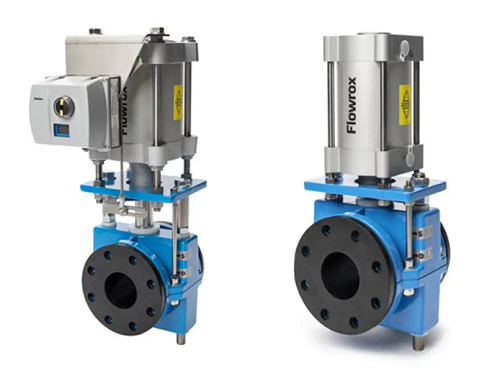

VALVESFlowrox™ slurry knife gate valves Isolate the flow in demanding conditions

Heavy duty slurry knife gate valve isolates flow even in the most demanding process conditions. The bi-directional flow tolerates backflow and elastomer sleeves on both sides of the gate provide tight shut off. Flowrox knife gate valve follows the concept of the ease of maintenance. The valve body is cast in one piece which eliminates the need for sealing between the body halves. Load distribution ring is integrated into the valve sleeves. The valve contains only two service parts; ring sleeves and secondary seal.

Technical Specifications

Series:

SKW

SKF

SKH

Size range:

50 - 600 mm / 2 - 24 in

80 - 1500 mm / 3 - 60 in

80 - 600 mm / 3 - 24 in

Pressure range:

up to 10 bar (145 psi)

up to 10 bar (145 psi)

up to 20 bar (290 psi)

Temperature range:

0 - 100 °C / 32 - 212 °F

0 - 100 °C / 32 - 212 °F

0 - 100 °C / 32 - 212 °F

Slurry wafer knife gate valve (SKW)

Slurry wafer knife gate valve (SKW) is designed for heavy duty purposes to isolate flow, even in the most demanding process conditions. The complete valve is built around an ease of maintenance concept and it contains only two service parts: ring sleeves and secondary seal.

- Improved performance – Integrated load distribution ring

- Ease of maintenance – Universal tower design

- Simple installation – One peace body with lockout pins

Slurry flanged knife gate valve (SKF)

Slurry flanged knife gate valves (SKF) are equipped with flanges. They isolate the flow even in the most demanding process conditions. They contain only two service parts: ring sleeves and a secondary seal.

- Improved performance – Integrated load distribution ring

- Ease of maintenance – Universal tower design

- Simple installation – One piece body with lockout pins

New design for big SKF valves

Knife gate valve actuator cylinders repositioned to the side

We have repositioned actuator cylinders to the side in bigger slurry knife gate valves over DN 900. The benefits are:

- Significantly reduced height – Easier to install, much less empty room above the valve is required.

- Increased safety – Installation and maintenance is not done high in the air.

- Easier maintenance – All maintenance access points are easily accessible, only 2 meters high from the ground.

High pressure knife gate valve for slurries (SKH)

Isolate the flow even with 20 bar pressure

Slurry knife gate valve (SKH) is designed for higher pressures (up to 20 bar) in heavy duty purposes to isolate the flow. Just as previously presented SKW and SKF valves, SKH valves also contain only two service parts: ring sleeves and gland packing.

- Ease of maintenance – Universal tower design

- Simple installation – One piece body with flushing ports

The SKH valves are available in sizes DN80–600.

Benefits of Flowrox KGV

- Bi-directional flow - Bi-directional flow tolerates backflow. 100% isolation.

- Free flow - Full bore enables free flow of process medium.

- Wear resistant - Only the ring sleeves in contact with the process medium.

- Simple to install and service - Face-to-face according to industry standards. Contains only two service parts; ring sleeves and gland packing.

- No over compression during installation - Integrated load distribution ring. (SKF, SKW) Steel retaining flange is supporting the ring sleeve (SKH)

Industries catered

- Mining, metals and steel

- Chemical

- Construction

- Food and beverage

- Energy

- Water and wastewater

Applications in Mining, Mineral and steel

- Metal refineries Our valves offering plays an important role in various metal refining processes for all commodities such as gold, copper, nickel, lithium and zinc. Whether your process is a hydro- or electrometallurgical plant or a smelter, our customers have trusted us with their flow control needs for decades. We offer extensive expertise and a wide portfolio of valve and pump solutions.

- Mineral processing and demanding Abrasive conditions in mineral processing require high performance and reliable process equipment. In Valmet’s Flowrox pinch valves and hose pumps, only wear-resistant rubber hoses come into contact with slurry, which guarantees long service intervals and easy maintenance. We have decades of experience in demanding slurry applications and have developed unique products that often outperform the standard products on the market.

- Slurry transportation Flow control valves are expected to have the highest reliability and most trouble-free operation in slurry transportation lines where the valves are not continuously monitored. Whether it is concentration sand or concentrate transportation, Valmet's Flowrox™ pinch valves and knife gate valves offer the longest service intervals and ease of use. We have decades of experience in demanding slurry applications and have developed unique valves to outperform the standard products on the market.

Industries usingAir Operated Double Diaphragm (AODD)

PartnersPartners who trust

Industrium co