Transformer is one of the main assets in the electrical power industry which needs to be maintained for guaranteed uninterrupted power transmission. Transformer oils are important for the functional transformers and are the dielectric substance that helps in maintaining their temperature. Transformer oils are vital for the proper running and functioning of the transformers

Transformers require filtered and dried oil. During its usage, the insulating oil absorbs moisture and gets polluted by sopping fibers, dirty particles, aging products, and soot. Even unused oil is not clean enough as it may have absorbed moisture from the air or may have got polluted in the barrel it was stored in. The efficiency of the oil as an insulating material is highly reduced as the moisture level increases.

Transformer oil filtration systems are used to remove moisture, dirt & oxidation products from the mineral based oil. This system works on low temperature & high vacuum application.

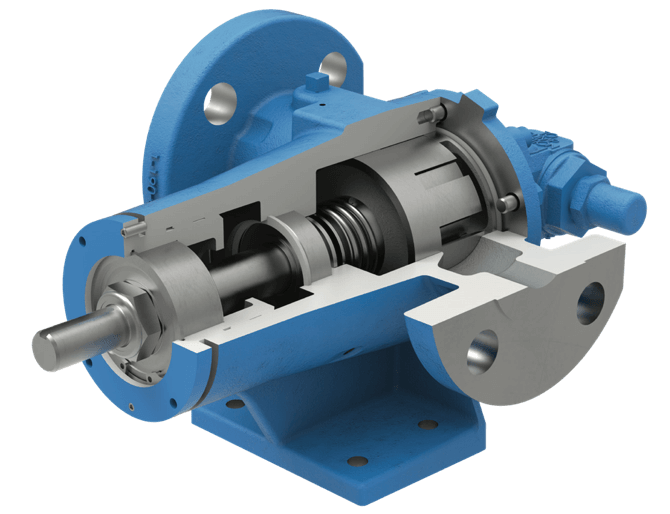

For the filtration systems, two number of gear pumps are required

- Suction pump

- Discharge pump

Suction pump: Application of this pump is only to feed the system with used transformer oil to the filtration system. On pump delivery side many systems manufacturers are using the filters to clean the final process oil. So discharge pressure of the pumps varies depending on the filters sizes

Discharge pump: This pump is very critical for functioning of the system properly. This pd pumps works under vacuum tank. The pressure of vacuum tanks are generally 0.1mbar. For this application pumps need to run at a low speed. With 1 meter suction line. And also selection of seal is also important. Else air can enter in the vacuum tank from pump.

Flow rate of both suction and discharge pumps are generally same.

Viking Pump Inc, USA has been pioneer in supplying pumps for many of the OEMs in the filtration systems. Feel free to contact us at info@madhavfluid.com or +91 98218 91092 for any questions related to this application.