RECIPROCATING

TechnologiesRECIPROCATING

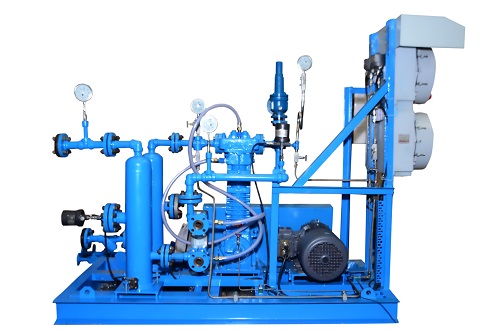

RECIPROCATINGProcess Gas Compression Packages

Process Gas Compression Packages Tailored for Excellence

At ABODEX, we craft bespoke gas compression packages that cater to niche applications within the process industry. Our non-lubricated process gas compressors, sourced from esteemed manufacturers like Blackmer and Mehrer, are the cornerstone of our systems. We import the bare block compressors from our principals in the US and Europe and meticulously engineer the entire system to meet the specific needs of your processes.

Our expertise extends to the engineering, procurement, and packaging of skid-mounted units, ensuring a streamlined solution from start to finish. We conduct thorough Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT) to guarantee performance and reliability. Furthermore, we offer comprehensive Annual Maintenance Contracts (AMC) or Annual Rate Contracts (ARC) to ensure the longevity and efficiency of your systems.

In addition to our non-lubricated compression solutions, we specialize in the manufacturing of rotary vane gas compression systems. Utilizing Sliding Vane compressors from RO-FLO USA, we design and assemble complete systems locally in India, providing tailored solutions to our diverse customer base.

Non-Lubricated Gas Compression Systems: Purity and Performance

Non-lubricated gas compression systems are engineered for applications where gas purity is paramount. The absence of oil in the compression chamber ensures that the discharge gas quality remains untainted, matching the purity of the inlet gas.

Features:

- Non lubricated / Oil Free construction

- Vertical, V, W type Reciprocating compressor

- Air cooled, / Water-cooled cylinder

- Single acting / Double acting piston

- Single or Double distance piece construction.

- Single and multi-stage compression

- Built-in / External Lubrication system for drive end parts

- Capacity control using Suction valve unloader / Bypass spill back loop / Speed variation.

- Rugged construction for 24x7 operation

- Highest pressure ranges up to 300 Bar g

- Compressor capacity ranging from 10 Nm3/hr to 2500 NM3/Hr.

- Max. power 300KW / Cylinder.

- Material of construction to suit application requirement.

- Safe & Reliable in operation

Gases we handle:

Ammonia, Propane, Butane, LPG, all type of Refrigerants, Butadiene, Propylene, Carbon Di-oxide, Carbon monoxide, Hydrogen, SO2, SF6, DMA, MMA, Isobutylene, Biogas, Natural gas, Mixed Hydrocarbon gas mixtures etc. and many more…

Application:

- Liquified gas transfer and vapour recovery

- Process gas recovery.

- Hydrogen recovery from Trolley

- Vapour recovery and liquification of gas.

- Pressure boosting and pipeline transfer.

- Vessel/sphere/Bullets – Evaluation

- Rescue gas transfer from mobile vehicle.

- Gas recycles.

- Moist gas recovery

Industries usingAccessories Of AODD & EODD

PartnersPartners who trust

Industrium co