LOBE

TechnologiesLOBE

VIKING Hygienic is efficient and gentle handling pumps making them perfect for applications like food and beverages or pharmaceutical with a number of material and finish options seal types & cleanability options. Viking Pump’s hygienic pumps offer the best efficiency and a wide range of porting, cleaning, and sealing options to meet your needs.

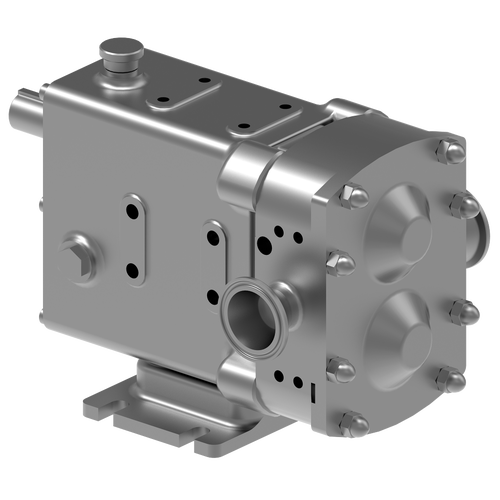

LobeHygienic Pump

- Lobe pumps operate by trapping a fluid between two or more rotating lobes and the pump casing.

- As the lobes rotate, they create a low-pressure area behind them, allowing the fluid to enter the space between the lobes and the casing.

- The fluid is then transferred through the pump as the lobes continue to rotate, creating a suction effect

Performance

- Capacity: upto 189 M3/Hr

- Pressure: upto 34 BAR

- VIscosity Range: 200000 cst

- Temperature: 0°C to 180°C

Sizes

- 1” to 6”

Material Of Construction & Configuration Option :

- PRODUCT WETTED (ROTORCASE, ROTORS, ROTOR RETAINERS, FRONT COVER): 316L stainless steel, other alloys also available

- GEARBOX (GEARBOX, MOUNTING FEET & BACK PLATES): Cast iron & stainless steel, dependent on pump series & size

- SHAFT SEALS: Single, single flushed & double mechanical seals; single & double O-ring seals; packed glands; composite seals, all dependent on pump series

Features And Benefits:

- Gauge Ports: Allow simple addition of local or remote monitoring systems

- Higher Pressure Capabilities: For long distance transfer of high viscosity liquids.

- Easy Timing: Rotors and gears are positively located on key shafts.

- Simple End Clearance Adjustment: Compared to other lobe pumps which require shimming.

- Excellent NPSHr: Fluid access on three sides of rotors enhances filling with highly viscous fluids and minimizes pulsation.

- Run Dry Continuously: Non-contacting rotors enable continuous run-dry with flushed seal, minimizing chance of failure due to operator error.

- Non-Contacting Pumping Principle: No metal-on-metal contact, avoiding pump wear regardless of product viscosity.

- Shaft Sealing Options: Include single, single flushed and double mechanical seals, single and double O-ring Seals, and packed glands.

- Low Shear Pump Design: Gentle handling of delicate and shear sensitive products.

- Solids Handling: Will handle a wide range of products including suspended solids.

- Front loading seals: can be changed while the pump is still in-line.

Typical Industries:

Common rotary lobe pump applications include, but are not limited to:

- Pharmaceutical & biotech, including vaccines

- Food products: processed meats, vegetables, sauces & condiments

- Confectionary: chocolate, fondants

- Beverages: alcoholic, soft

- Dairy products: milk, cheese, yogurts

- Personal care products: shampoo, soaps, deodorants, cosmetics

- Pet foods

- Pulp & paper

- Chemicals: lubricants, paints & pigments, polymers

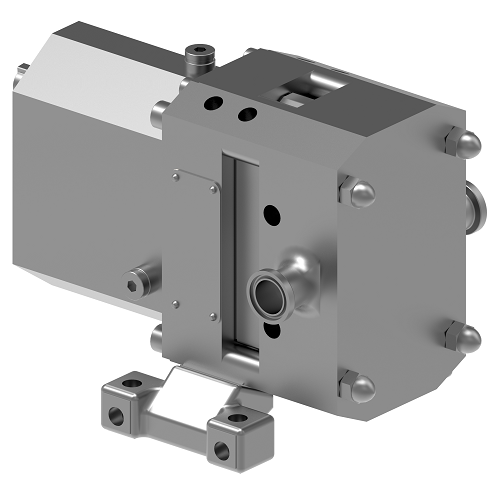

LobeMulti Lobe Pump (Mp)

Ideal for pharmaceutical, hygiene, food products and more, with their ease of service, superior performance and simplicity of maintenance

Performance

- Capacity: upto 189 M3/Hr

- Pressure: upto 12 BAR

- VIscosity Range: 200000 cst

- Temperature: 0°C to 180°C

Rotor & Casing Options:

- 316L stainless steel pump casing with interior finished to 3-A standards

- 316L stainless steel rotors

- Improved surface finishes & electropolishing optional

- Front cover jacket or rotor case saddles

Gear Box:

- Powder-coated or painted standard (size dependent)

Sealing:

- Single O-ring

- Single mechanical

- Single mechanical with flush or quench

- Double mechanical with flush

- Gland packing

- Gland packing with lantern ring with flush.

Surface Finish:

- 0.8µm to 0.4µm internal finish

Porting:

- Complete range of hygienic clamp, screw, flange & industrial screw connections

- Tri-clamp, flanged, DIN, IMDA, NPT, BSP, etc.

- Rectangular port

Features & Benefits:

Cleanability

- Modular pump design promotes easy disassembly for COP (Clean Out of Place) & CIP (Clean in Place)

- Casing profile cusps maximize efficiency & draining capability

Performance

- Timed, non-contacting rotors minimize shear while providing extended run-dry capability

- Helical timing gears provide high torque & quieter operation for extended pump life

- Tapered roller bearings provide higher operating speeds & better discharge pressures

Ease Of Maintenance

- Removable foot for easier placement

- Classic RLP design

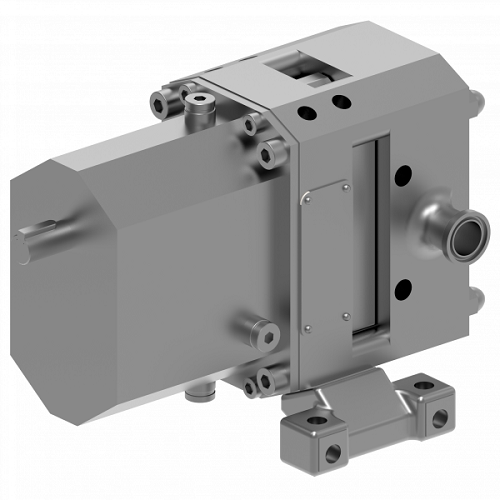

LobeRevolution® Series Pump

Offering both rotating lobe and circumferential piston rotor options, is ideal for pharmaceutical, hygienic, food products and more, with its ease of service, superior performance and simplicity of maintenance.

Spanish mackerel yellow weaver sixgill. Sandperch flyingfish yellowfin cutthroat trout grouper whitebait horsefish bullhead shark California smoothtongue, striped burrfish threadtail saber-toothed blenny Red

Performance

- Capacity: upto 91 M3/Hr

- Pressure: upto 31 BAR

- VIscosity Range: 440000 cst

- Temperature: 0°C to 150°C

Rotor & Casing Options:

- Non-galling WFT 808® nickel alloy standard for CPP316L stainless steel rotors

- 316L standard for RLP and optional for CPP

- Optional clearances: front face, hot, high temperature/high viscosity (chocolate)

Gear Box:

- Powder coated cast iron standard

- Stainless steel optional

- Oil lubrication standard, grease optional

Sealing:

- Single mechanical

- Double mechanical with flush

- Single O-ring running on a replaceable sleeve

- Double O-ring w/ flush running on a replaceable sleeve

- Complete range of material options

Porting:

- Hygienic port options: Tri-clamp, DIN 11864, DIN 11851 Male, SMS Male

- Industrial port options: ASA/ANSI 150 lb. or 300 lb. RF, DIN 2633, BSP Male, NPT Male

- Rectangular flange/hopper inlet available on select sizes

- Pumps may be fitted with front cover and rotor case jackets when required

Surface Finish:

- Standard 32 RA internal finish

- Optional mechanical internal finishes: 24 RA or 16 RA

Features & Benefits:

Cleanability

- Efficient CIP (Clean In Place) ability is standard for all Revolution pumps

- Self draining pump head from innovative cusps & cusp reliefs

Ease Of Maintenance

- Fast, front loading seal changes while pump is still in line Seal positioned for optimal lubrication, maximizing seal life.

- Front access shimming for setting rotor clearance significantly reduces maintenance time

- Convenient preventive maintenance parts kits available

Performance

- Improved volumetric efficiency in low & high viscosity applications

- Up to 15% better flow performance than competitors’ CIP configuration with CPP version

- Gentle handling of solids & shear sensitive products

- Long-life durability from heavy duty shafts, bearings & helical gears

- Less overhung load

LobeSterilobe Pump

For pharmaceutical, food and beverage and more, thanks to its ability to handle products delicately and hygienically

Performance

- Capacity: upto 170 M3/Hr

- Pressure: upto 15 BAR

- VIscosity Range: 200000 cst

- Temperature: 0°C to 150°C

Rotor & Casing Options:

- 316L stainless steel pump casing with interior finished to Ra of 24µin (0.6µm).

- 316L stainless steel rotors

- Improved surface finishes & electropolishing optional

- Bi-wing rotors standard

Sealing:

- Single mechanical

- Single mechanical with flush or quench

- Double mechanical with flush

Porting:

- Complete range of hygienic clamp, screw, flange & industrial screw connections

- Tri-clamp, flanged, DIN, IMDA, NPT, BSP, etc.

Features & Benefits:

Cleanability

- Cover joint profile improves hygienic characteristics & self-draining capabilities

- Clean & corrosion resistant stainless gear cover & powder coated bearing housing

Ease Of Maintenance

- Front loading seals can be changed while the pump is still in-line

- Seal positioned for optimal lubrication, maximizing seal life

- Hassle free gearbox maintenance with sealed for life bearings

Performance

- Standard bi-wing rotors offer application flexibility & good solids handling capabilities

- Multi-lobe rotors reduce shear & pulsation effect; ideal for sensitive media

- Innovative cusps with reliefs allow for easier cleaning and self draining with improved efficiency

Industries usingAir Operated Double Diaphragm (AODD)

PartnersPartners who trust

Industrium co