POSITIVE DISPLACEMENT PUMPS

TechnologiesPOSITIVE DISPLACEMENT PUMPS

A positive displacement pump transports fluids by trapping a fixed amount of the liquid and forcing it into the discharge pipe. The movement is started by two or three spindles that move in opposite directions of each other; pumping and thus displacing the liquid.

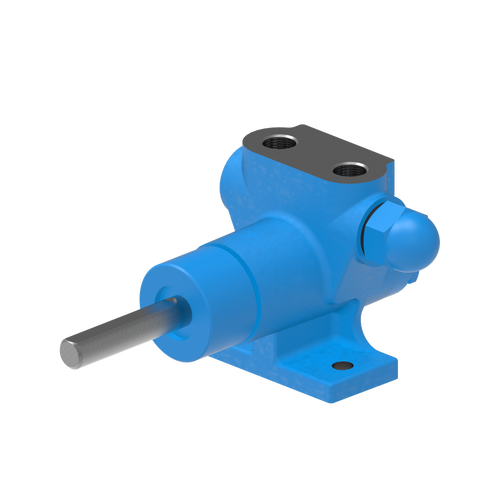

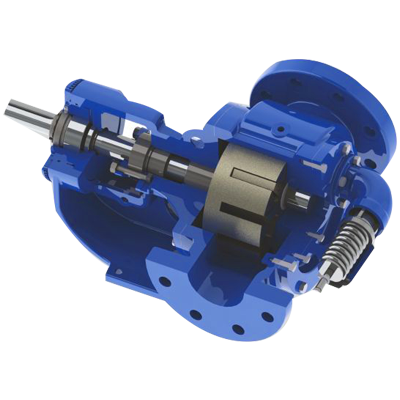

Gear PumpWorking Principle Of Gear Pump:

The Gear pump is a rotary positive displacement pump that moves fluid using the rotary motion of the pumping elements.

- Liquid enters the suction port between the teeth of the rotor gear (Driver gear) and the idler gear (driven gear).

- The intermeshing of both gears form locked cavities for the liquid to ensure volume control. As the teeth come out of mesh, low pressure zones are created at the suction port, pulling liquid into the spaces.

- The liquid continues to travel through the pump, between the teeth of the gear-within-a-gear principle.

- When the teeth mesh completely, liquid is forced out of the spaces and out of the discharge port.

ADVANTAGES/ FEATURES :

Reliable & easy to maintain.

- Only two moving parts (gears). Less moving parts results in less wear and tear

Shaft seal options.

- Including packed gland, lip seal, Component seal, Cartridge seal & mag drive (seal less) options

Porting options

- VIKING’S broadest selection of port locations, configuration & types are convenient to meet customer’s piping requirement.

- Minimal pulsation For accurate flow measurement

- One shaft seal More reliable & lower cost than two or four seals used on timed lobe & screw pumps

- Long seal and bearing life (Generally operated at speeds from 250 to 1750rpm, for reduced seal and bearing wear)

- Low shear (Selection of proper pump and speed to protect shear sensitive liquids)

- Low NPSHr (Enables suction lift or pulling from vacuum vessel)

- Flow proportional to speed (Provides easy control of flow rate with variable speed drive for excellent metering capabilities)

- Handles any viscosity (Capable of handling 28 to 2000000 SSU)

- Simple maintenance (Seal, head and shaft replacement can usually be done in place without removing pump from piping)

- Self-priming (Enables priming if pump is above liquid level. Some VIKING pumps are capable of suction lifts up to 20ft i.e., 6mtr)

- Reversible direction of flow (Use same pump for loading and unloading or line stripping)

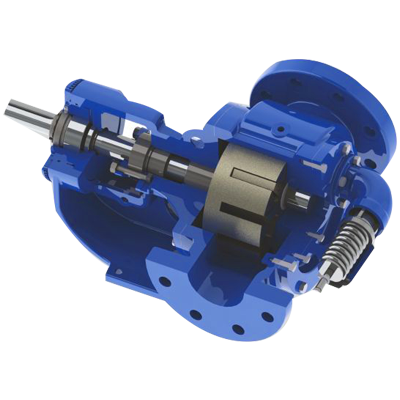

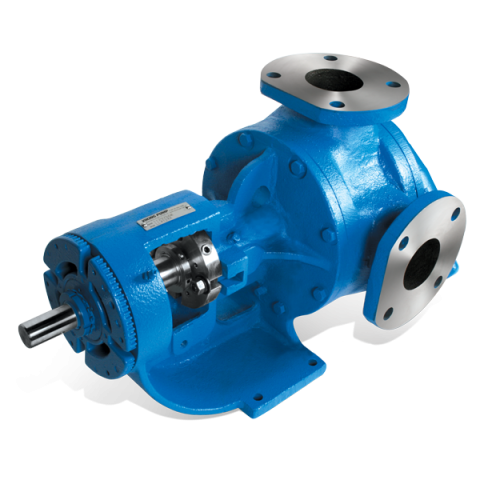

Gear PumpViking Internal Gear Pump

Internal Gear pumping principle was pioneered by VIKING pump over 100 years ago and continues to be one of Viking’s most renowned products.

Viking General Purpose:

Viking Series 32 pumps are extremely well suited for light, medium and intermittent service handling a variety of liquids. Viking’s unique and unusually simple pump construction makes it adaptable to many diversified installations. The pumps possess excellent vacuum characteristics and will operate and prime at suction lift- up to 25 feet. It can be provided with extended shaft for special applications.

Performance

- Capacity: Maximum to 102 m3/hr

- Viscosity: 0.1 to 55,000 cSt

- Discharge Pressure: Maximum to 17 bar.

- Suction Pressure: Vacuum to 30 bar.

- Temperature: -85 ºC to 250 ºC

Material Of Construction & Configuration Option:

- Externals (Head, Casing, Bracket)

Cast iron,.

INTERNALS (ROTOR, IDLER)

Steel, Cast iron.

INTERNALS (ROTOR, IDLER)

Steel, Cast iron.

- Bushings (Sleeve Bearings)

Carbon graphite, bronze, hardened cast iron, silicon carbide, tungsten carbide, and other specials materials as needed.

- Shaft Seal

Lip seals, packing, Single mechanical seals.

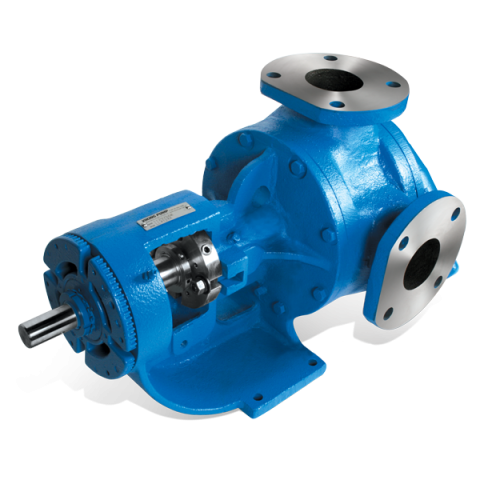

Gear PumpUniversal Product Line

The Universal Product Line has the broadest range of sealing options of all pumps built by Viking. The stuffing box on all sizes accepts packing, numerous component single mechanical seals, or a wide variety of cartridge seals.

The Universal Product Line is Viking Pump’s most versatile line of internal gear pumps due to the availability of many design and material options.

Performance

- Capacity: Maximum to 363 m3/hr

- Viscosity: 0.1 to 440,000 cSt

- Discharge Pressure: Maximum to 17 bar.

- Suction Pressure: Vacuum to 30 bar.

- Temperature: -85 ºC to 250 ºC

Material Of Construction & Configuration Option:

- Externals (Head, Casing, Bracket)

Cast iron, ductile iron, steel, stainless steel, and other alloys.

- Internals (Rotor, Idler)

Cast iron, ductile iron, steel, hardened steel, stainless steel, and other alloys.

- Bushings (Sleeve Bearings)

Carbon graphite, bronze, hardened cast iron, silicon carbide, tungsten carbide, and other specials materials as needed.

- Shaft Seal

Lip seals, packing, O-Pro seals, component mechanical seals, industry-standard cartridge mechanical seals, API 682 seals, special for abrasive liquids, and seals less magnetic couplings.

Special Features

- Jacketing & Heat Tracing:

Comes with jacketing and electrical heat tracing option for high temperature and temperature sensitive liquids.

- Adjustable End Clearances:

For low or high viscosities, high temperatures, or to compensate for wear over time.

- Sealing option:

Can accommodate any seal because of big stuffing box.

Gear PumpMag Drive Pump

The Mag drive Series is the ideal sealing technology within Viking’s Product Line pumps.

In this Canister is hermetically sealed, providing the highest level of liquid containment available by eliminating traditional dynamic shaft seals traditionally associated with hazardous, hard-to-seal, or expensive liquids. It also eliminates housekeeping issues and downtime due to seal failure. This product is designed to handle a broad range of applications (such as caustics, isocyanates, adhesives, solvents and mercaptans). the Mag drive series may be run dry for short periods, such as for clear lines when unloading, or in the case of accidental empty tank situations.

Performance

- Capacity: Maximum to 363 m3/hr

- Viscosity: 0.1 to 440,000 cSt

- Discharge Pressure: Maximum to 17 bar.

- Suction Pressure: Vacuum to 100 bar.

- Temperature: -85 ºC to 250 ºC

Material Of Construction & Configuration Option:

- Externals (Head, Casing, Bracket)

Cast iron, ductile iron, steel, stainless steel, and other alloys.

- Internals (Rotor, Idler)

Cast iron, ductile iron, steel, hardened steel, stainless steel, and other alloys.

- Bushings (Sleeve Bearings)

Carbon graphite, bronze, hardened cast iron, silicon carbide, tungsten carbide, and other specials materials as needed.

- Shaft Seal

Seal less magnetic coupling.

Special Features

- Stepped housing keeps the outer magnet from contacting the canister in the unlikely event of bearing failure.

- Adjustable end clearance for fluid viscosity or temperature by use of head shims.

- Short-term Run-dry Capability. Unlike many mag drive.

- Positive Cooling Flow minimizes potential for thermal product degradation and to cool the magnet area.

- Can run on motor speed for thin liquids.

- Have options like internal gear, External gear, Helical gear also.

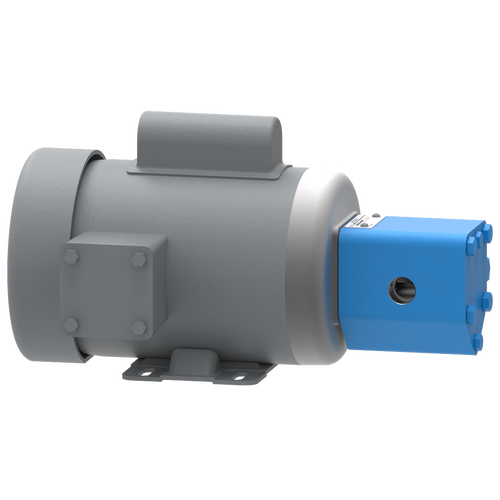

Gear PumpMotor Speed Pump

Viking’s Motor Speed Product Line internal gear pumps represent a technological advance in the science of flow with thin liquids. Through new techniques of feeding the rotor and idler, Viking has achieved what was once considered impossible – high flow rates operating at motor speeds.

Performance

- Capacity: upto 132 M3h

- Viscosity: upto 8000cSt

- Pressure: upto 17 bar.

- Temperature: -40 ºC to 150 ºC

Material Of Construction & Configuration Option:

- Externals (Head, Casing, Bracket)

Cast iron, ductile iron, steel, stainless steel, and other alloys.

- Internals (Rotor, Idler)

Cast iron, ductile iron, steel, stainless steel, and other alloys.

- Bushings (Sleeve Bearings)

Carbon graphite, bronze, hardened cast iron, silicon carbide, tungsten carbide, and other specials materials as needed.

- Shaft Seal

Single mechanical, Seal less magnetic coupling.

Special Features:

Direct drive with no gear reducer

- Reduces cost of installation

- Eliminates one shaft alignment.

- Eliminates one set of couplings and coupling guard.

- Reduces footprint.

- Eliminates gearbox lubrication and maintenance.

Heavy duty design with sealed-for-life bearings

- No relubrication required.

- Thrust control enables high pressure capabilities.

- Enables end clearance adjustment for viscosity or to compensate for wear over time.

Behind-the-rotor mechanical seals

- Eliminates bracket bushing, enables use of antifriction bearing external to liquid.

- Heavy duty seal provides broad application, long life.

- Casing weep hole between seal and forward bearing enables detection of seal leakage, prevents intrusion into sealed bearing.

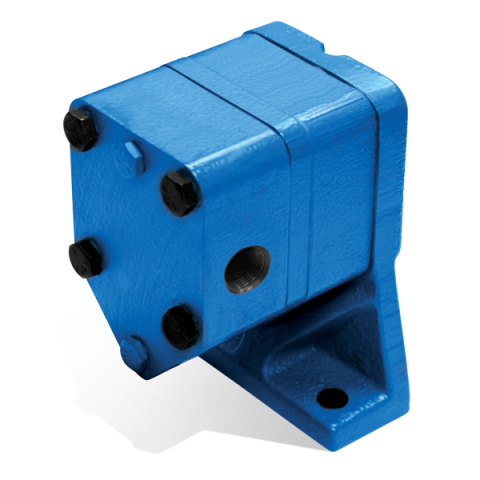

Gear PumpExternal Gear Pump

Viking external gear is an extensive series of precision, industrial-duty external gear pumps that develop higher pressures and offer a similarly broad range of options to handle a diverse range of liquids and applications.

These pumps were designed for greatest reliability, with standard features like spur-type gears, helical gears and rolling element anti-friction bearings (instead of bushings, which wear every time a pump is stopped, and the hydrodynamic film is lost).

Unwanted leaks are prevented by using the best sealing technology available, including single or duplex lip seals, single mechanical component seals.

- Bearing support on both sides of the gears enables differential pressures to 500 PSI (34 BAR), or Intermittent to 2,500 PSI (170 BAR)

- Motor speed operation eliminates cost of speed reducer.

- Eliminates lubrication – no external axial or radial bearing required in most applications.

Performance

- Capacity: upto 190 GPM

- Viscosity: upto 1000cSt

- Pressure: upto 34 bar (Intermittent 170 Bar)

- Temperature: -40 ºC to 175 ºC

Material Of Construction & Configuration Option:

- Externals (Head, Casing, Bracket)

Ductile iron, carbon filled PVDF.

- Internals (Shafts)

Steel, alumina ceramic

- Internals (Gears)

Steel, carbon filled PTFE.

- Bushings (Sleeve Bearings)

Carbon, silicon carbide, needle bearings

- Shaft Seal

Lip seal, component mechanical seal, seal less magnetic couplings.

Special Features:

- Higher Pressure Capabilities: With shaft support on both sides of the gears

- Shaft Extension Options: Include keyed, tang and spline.

- Shaft Seal Options: Including lip seal, component mechanical seal and seal less mag drive options

- Compact, Close-Coupled Options: For motor speed operation or with gearmotors

External Gear Pump's Market & Applications

Polymers

- Rubbers & Plastics

- Fibers & Resins

- Polyurethanes

Oils

- Crude oils

- Lube oil & Grease

- Asphalt & Bitumen

Fuels

- Refined fuels

- Biofuels

- Liquified gases

Pharmaceutical

- Medicinal chemical

- Creams & ointments

- Blood & plasma processing

Chemicals

- Acids & Bases

- Alcohols & Solvents

- Soaps & Detergents

Machnery

- Fuel & lube

- Heat transfer liquids

- Filtration

Foods

- Liquid sugars

- Chocolate & confectionery

- Edible oils

Dairy

- Butter

- Cheese

- Cream

Pulp & Paper

- Coatings

- Starch

- Black liquor soap

Personal Care

- Lotion & Creams

- Toothpaste

- Hair & skin care

Water & Wastewater

- Methanol

- Polymers

- Additives

Coatings & Sealants

- Paints, dyes & inks

- Adhesives

- Caulks

Beverages

- Distillers & Vinters

- Fruit & vegetables

- Carbonated drinks

Industries usingAir Operated Double Diaphragm (AODD)

PartnersPartners who trust

Industrium co