DOSING PUMP

TechnologiesDOSING PUMP

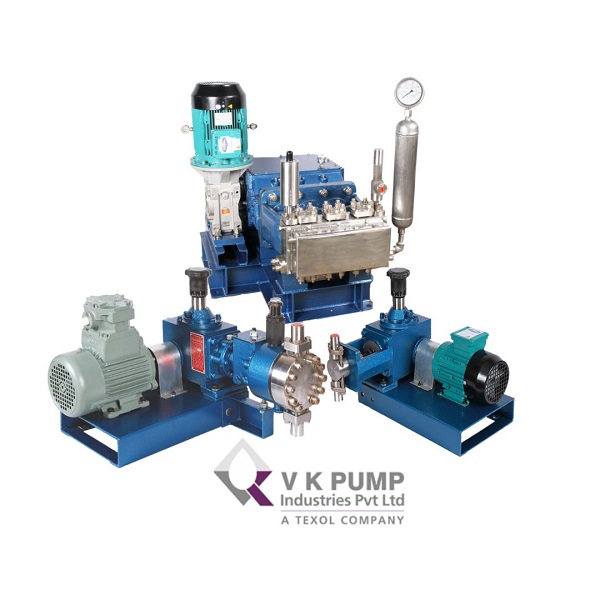

DosingDosing Pump

Working Principle:

The dosing pump operates on a straightforward yet precise working principle, utilizing a reciprocating motion to deliver a specific volume of liquid or chemical into a process fluid or system. This action is typically powered by an electrical motor or pneumatic supply, which drives a piston or diaphragm within the pump. As the piston or diaphragm moves back and forth, it draws the liquid into the pump chamber during the suction phase as the inlet valve opens. Conversely, during the discharge phase, the inlet valve closes, and the outlet valve opens to release the liquid into the system.

Pump itself acts as a standalone metering device as it is equipped with a manual stroke length control mechanism which helps to vary pump capacity within 10:1 turn down. Pump capacity variation can be automated using auto stroke length controller or using VFD based speed control.

API 674 & API 675 metering pump are classified in 2 categories

- Plunger Pump

- Hydraulically Actuated Balanced Diaphragm pump (Leak Proof design)

Performance

- Steady State Accuracy: +/- 1% of rated flow

- Linearity: +/- 3%

- Repeatability: +/- 3%

- Turndown Ratio: 10:01

- Design for 10% Higher capacity

- Design: Plunger & Hydraulically Actuated

- Flow<1 to 10,000 LPH with single head

- Pressure: 300 bar

Customised Options:

- Remote head

- Jacketed

- Automatic Stroke Length Controller (Electrical, Pneumatic)

- Multi head pump with single drive

- Diaphragm leak detection System

- Multi head construction

Material Of Construction & Configuration Option :

- HEAD: SS316/316L, Polypropylene, PTFE, Hastelloy C, Alloy20, Monel

- DIAPHRAGM: PTFE, Hastelloy C

Typical Applications:

Common AODD applications include, but are not limited to:

- Oil & Gas Industry (Onshore and Offshore)

- Petrochemical

- Chemical Process

- Energy & Power (Power Plants, Desalination, Cooling Towers)

- Food and Pharmaceuticals

- Ceramics and Steel Industry

- Paper & Pulp

- Textile

- Water Treatment

- Sugar

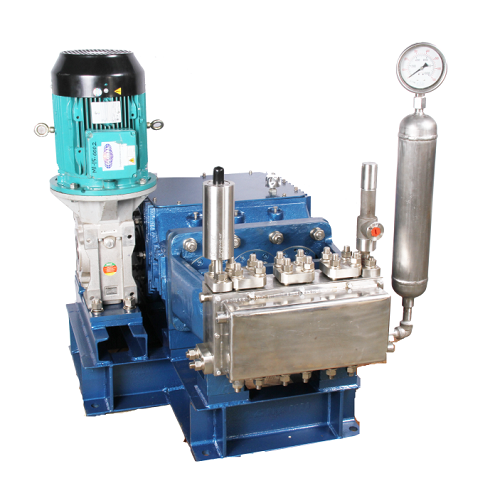

Metering PumpMetering Pump API 674

An API 674 Pump is a type of Positive displacement pump for reciprocating plunger pumps as well as Diaphragm Pump. These pumps are designed for high flow rate at High pressure applications and are known for their cost-effectiveness and efficiency. This pump is a fixed capacity transfer pump.

These pumps are often used in offshore process applications such as Chemical injection, Sea water and produced water injection, Glycol circulation, MEG injection etc.

Performance:

- Steady State Accuracy: +/- 1% of rated flow

- Linearity: +/- 3%

- Repeatability: +/- 3%

- Turndown Ratio: 5 :1 (Speed reduction using VFD)

- Design for 10% Higher capacity

- Flow< 100 to 40,000 LPH with single head

- Pressure: 400 bar

Material Of Construction & Configuration Option:

- HEAD: SS316/L, Hastelloy C, Monel

- DIAPHRAGM: PTFE / Metal Diaphragm, Unique design with leak detection, High pressure and temperature

Industries usingAir Operated Double Diaphragm (AODD)

PartnersPartners who trust

Industrium co