AIR OPERATED DOUBLE DIAPHRAGM PUMP

TechnologiesAIR OPERATED DOUBLE DIAPHRAGM PUMP

The SANDPIPER air-operated double-diaphragm (AODD) product portfolio offers unique series options that have been designed as solutions for most challenging and critical problems. Over five decades of innovation have resulted in many class-leading options to provide the perfect pump for unique application needs.

AODD PumpsWorking Principles

- Air-Operated Double Diaphragm (AODD) pumps are powered by compressed air or nitrogen.

- The main directional (air) control valve distributes compressed air to an air chamber, exerting uniform pressure over the inner surface of the diaphragm. At the same time, the exhausting air from behind the opposite diaphragm is directed through the air valve assembly(s) to an exhaust port.

- As inner chamber pressure exceeds liquid chamber pressure, the rod connected diaphragms shift together creating discharge on one side and suction on the opposite side. The discharged and primed liquid’s directions are controlled by the check valves (ball or flap) orientation.

- Once actuated, the pilot valve sends a pressure signal to the opposite end of the main directional air valve, redirecting the compressed air to the opposite inner chamber.

Performance

- Max. Capacity: upto 1173 LPM

- Max. Pressure: upto 17 BAR

- Solid Handling: upto 75 MM

- Temperature Range: -40 ºC to 177 ºC

Sizes

- ¼", 1/2", 1”, 1.5", 2", & 3"

Material Of Construction & Configuration Option :

Metallic

- SS316, Aluminium, Cast Iron, Alloy C, Hastelloy

Non-Metallic

- Polypropylene, Acetal, PVDF, Conductive Polypropylene, Conductive acetal, Conductive PVDF

Diaphragm

- PTFE, Santoprene, Neoprene, Viton, EPDM, Nitrile, Hytrel, UHMW, Carbon Steel

Porting

- BSP/NPT

- Flanged (ANSI or DIN Compatible)

- Dual Porting

- Tri-clamped

Advantages

- Sealless Design

- Self-priming

- Dry-Running

- Deadheads Safely

- No Electrical Installation Required

- Low Shear & Degradation of product

- Solid Handling Capacity

- Lightweight & Portable

Typical Applications

Common AODD applications include, but are not limited to:

- Automotive

- Chemical

- Ceramic

- Paints & Coatings

- Pulp & Paper

- Oil & Gas

- Mining

- Construction

- Waste Water

- Marine

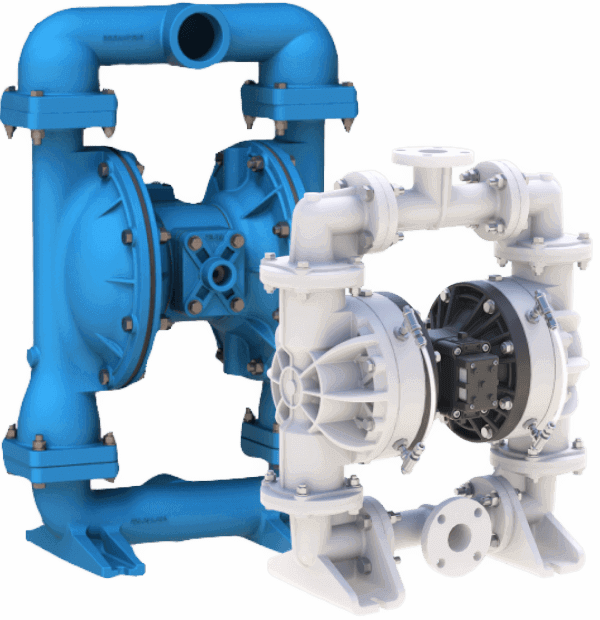

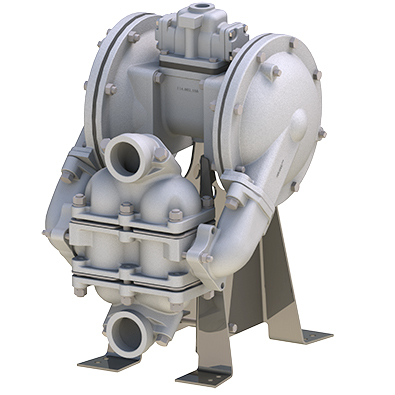

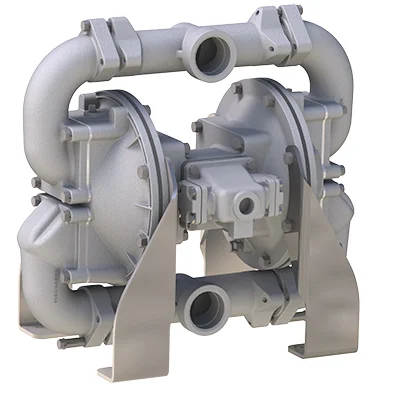

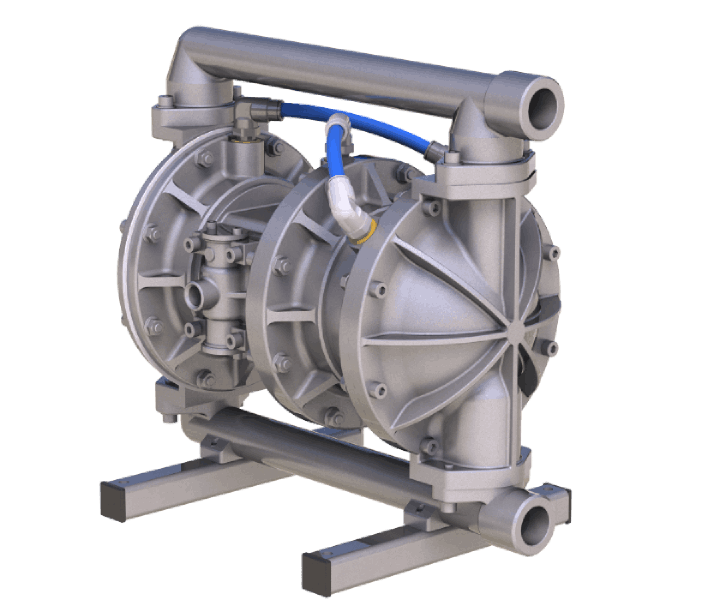

AODD Pump TypeStandard Duty Ball Valve

Perfectly designed for intermittent or on-demand use, portability, handling moderately abrasive fluids, and managing suspended solids

Performance

- Max. Capacity: 1079 LPM

- Max. Pressure: 8.6 BAR

- Solid Handling: 18 MM

- Temperature Range: -40 ºC to 177 ºC

Features & Benefits

- Bottom suction & Top discharge

- Ball Check Valves ensures powerful, high flow pumping

- Dry primes up to 20' of water

- Externally Serviceable Air Distribution System

- Dynamic Manifold Connections (90° - 180° rotation options)

- All Bolted Construction ensures Durability and high-pressure capacity

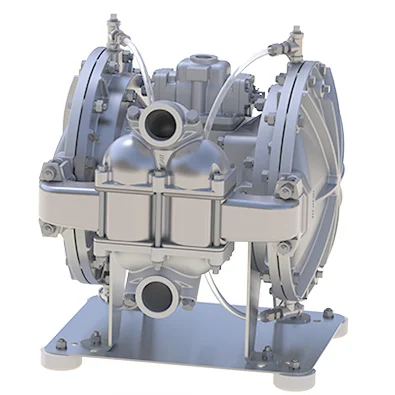

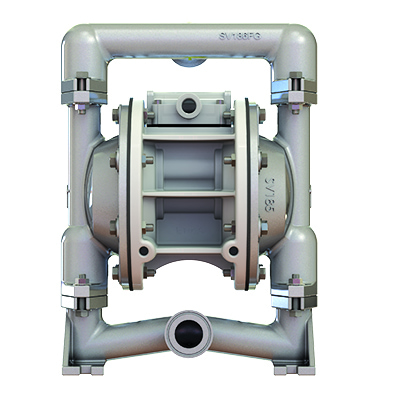

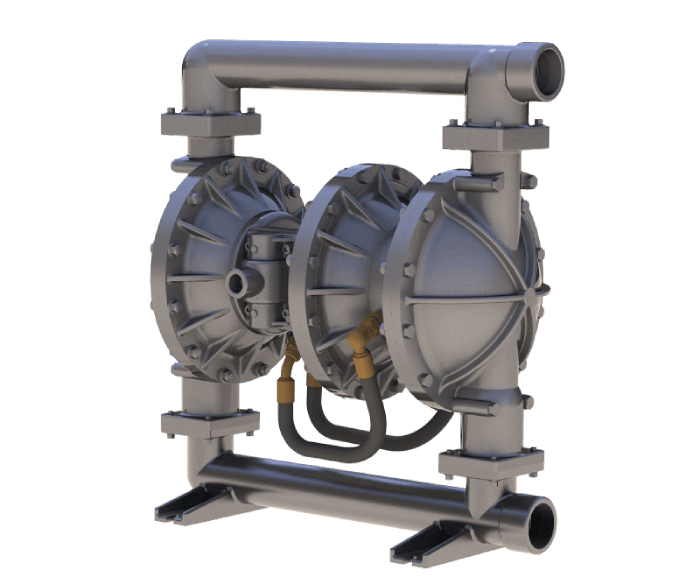

AODD PumpsContainment Duty Ball Valve

Perfectly designed for intermittent or on-demand use, portability, handling moderately abrasive fluids, and managing suspended solids

Performance

- Max. Capacity: 988 LPM

- Max. Pressure: 8.6 BAR

- Solid Handling: 10 MM

- Temperature Range: -40 ºC to 177 ºC

Features & Benefits

- Bottom suction & Top discharge

- Ball Check Valves ensures powerful, high flow pumping

- Dry primes up to 18' of water

- Ideal for highly corrosive and hazardous chemical fluid requirements

- Two diaphragms on one side consisting buffer liquid in between ensures no leakage

- Designed to accommodate visual, mechanical and low voltage leak detection devices.

- Hydraulically balanced / coupled pumping and driver diaphragm assemblies

- Externally Serviceable Air Distribution System

- Dynamic Manifold Connections (90° - 180° rotation options)

- All Bolted Construction ensures Durability and high-pressure capacity

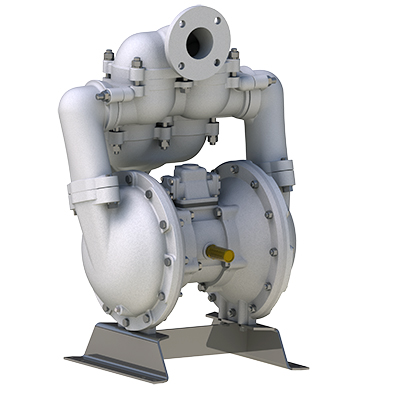

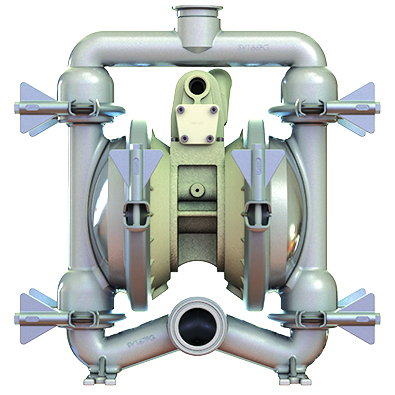

AODD PumpsHeavy Duty Ball Valve

To handle abrasive slurries, viscous liquids, or mixtures with solid particles with Weighted check balls (30-60% heavier than solid rubber check balls, allowing for more consistent chamber filling)

Performance

- Max. Capacity: 1136 LPM

- Max. Pressure: 8.6 BAR

- Solid Handling: 22 MM

- Temperature Range: -40 ºC to 177 ºC

Features & Benefits

- Ideal for thin to highly viscous and small solids-laden fluids

- Exclusive variable porting options (side, top, bottom and dual)

- Enhanced with an extended wear package

- Ball Check Valves ensures powerful, high flow pumping

- Externally Serviceable Air Distribution System

- Dynamic Manifold Connections (Can be vertically or horizontally mounted)

- All Bolted Construction ensures Durability and high-pressure capacity

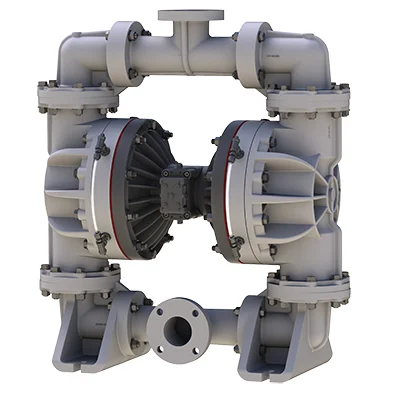

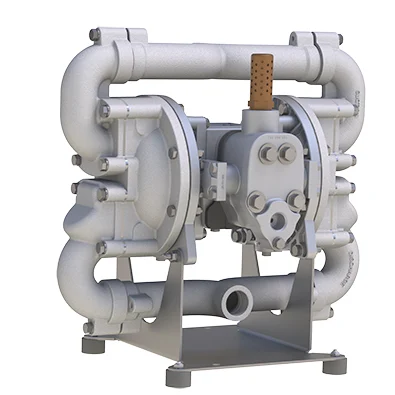

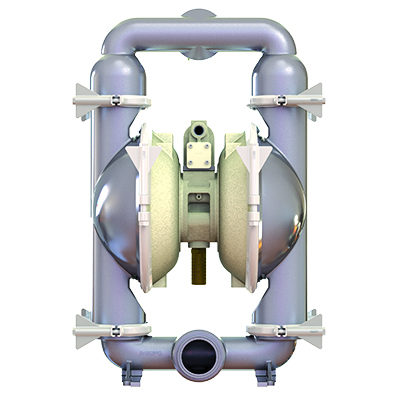

AODD PumpsHeavy Duty Flap Valve

Proven and trusted solution, even in the harshest applications, pump which effortlessly moves abrasive slurries, suspended and non-suspended solids, as well as line-size solids

Performance

- Max. Capacity: 1173 LPM

- Max. Pressure: 8.6 BAR

- Solid Handling: 75 MM

- Temperature Range: -40 ºC to 177 ºC

Features & Benefits

- Ideal for abrasive slurries, suspended and non-suspended solids & line-size solids requirements

- Pumps up to line size solids

- Bottom discharge porting, discharges settling solids

- Superior suction lift of up to 24 ft

- Flap Check Valves provide large solid abilities

AODD PumpsPremium FDA Compliant

compliant with FDA standards and certified according to EC 1935, are well-suited for food and beverage processing, pharmaceutical, and cosmetic industry applications that require electropolished surfaces.”

Performance

- Max. Capacity: 1078 LPM

- Max. Pressure: 8.6 BAR

- Solid Handling: 9.5 MM

- Temperature Range: -40 ºC to 177 ºC

Features & Benefits

- Ideal for a variety of food processing, pharmaceutical and cosmetic industry applications

- Electropolished 316 and 302/304 Stainless Steel Components

- Clean-in-place or clean-out-of-place applicable

- Bolted (T series) as well as clamped (F Series) construction

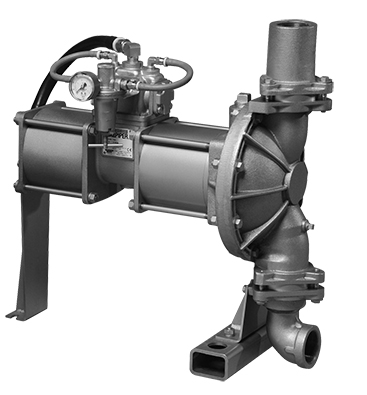

AODD PumpsHigh Pressure

Delivers nearly double the force in applications where pressure takes priority and excellent flow rates are essential, is specifically designed for thick, viscous fluids (with high specific gravity), high head pressure applications, and long-distance fluid movement

Performance

- Max. Capacity: 454 LPM

- Max. Pressure: 16 BAR

- Solid Handling: 46.8 MM

- Temperature Range: -40 ºC to 177 ºC

Features & Benefits

- Delivers discharge pressure twice the air inlet pressure

- Designed for filter press feed and applications requiring higher discharge pressures

- Non-Freezing, Non-Stalling, Patented air valve will never unexpectedly stop

- Rugged leak free bolted design

Industries usingAir Operated Double Diaphragm (AODD)

PartnersPartners who trust

Industrium co