In a Dec 2008 survey of industrial pump users, top three of 12 identified needs were “eliminating leakage”, “simple installation, operation, and maintenance”, and “minimizing energy uses.” Any pump user will vouch that no. 1 cause of pump failure is mechanical seal leakage.

Conventional shaft sealing methods include packing rings, lip seals, single mechanical seals, tandem and double mechanical seals. Shaft packing rings are designed as controlled leakage devices and must be permitted to leak (10-20 drops/ min) to stay lubricated and to minimize shaft wear and damage. Lip seals have very low pressure ratings, and have generally low life expectancy under good conditions.

Mechanical seals are widely used on industrial pumps and can provide satisfactory life. However, the seal faces (rotary and stationary) must be lubricated with a thin film of liquid to minimize friction and carry away the heat generated. This film of liquid typically evaporates in the atmosphere and there is no visible leakage. However, as seal faces start to wear the leakage becomes more evident, requiring pump to remove for rebuilding the seal.

So which sealing medium will you use for liquids that are difficult to seal or hazardous? Tandem and double mechanical seals were typically used for such services. These arrangements are quite elaborate and expensive; therefore, demand high skill and high operation and maintenance cost.

Peristaltic, Canned motor, and sealless magnetically coupled pumps are available as alternative solutions. We will discuss more about sealless magnetically coupled pumps in this blog.

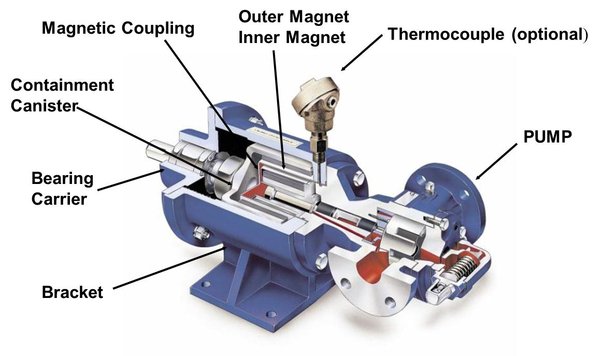

While sealless mag-drive centrifugal pumps are in existence since early 50s, magnetic drive rotary pumps came into prominent use in the 90s. Magnetic drive solves the problem of shaft leakage by eliminating the dynamic seal where the rotating shaft passes through the pump casing to connect with the drive. Liquids are hermetically sealed inside a containment canister with a static seal. Typically an inner magnet assembly is connected to the pump shaft within the canister, and an outer magnet assembly is mounted outside of the canister. The outer magnet assembly is connected to the drive so that as it rotates, magnetic force passes through the canister and, in turn, causes the inner magnet assembly and pumping element to rotate.

Viking® Mag-drive Internal Gear Pump Pump

Mag-drive pumps are extensively used for applications including:

- Hazardous liquids: Liquids such as strong acids, bases, oxidizers, very hot or very cold liquids, carcinogens, which are hazardous to humans

- Flammable liquids: Causing fire hazard

- Cosmetic reasons: Eliminate routine housekeeping from clean up of seal leakage

- Costing monitoring and reporting of leakage under the Clear Air Act: National Environment Standards for Hazardous Air Pollutants (NESHAP) require weekly monitoring and reporting of pumps handling certain chemicals with packing or single mechanical seal

- Less MTBF (Mean Time Between Failure) for critical applications: Unplanned downtime is lost production, with the complexities of shutdown and start-up, as well as wasted product

- Difficult to seal liquids: Liquids such as isocyanates (TDI/ MDI), alkyd resins etc. form crystals on seal faces and cause premature wear when in contact with air.

- Expensive Liquids: Where few drops of leakages can cost significantly

- High suction pressure: Refrigerants, pipeline sampling

Mag-drive pumps are offered by most international manufacturers of PD rotary pumps including internal gear, external gear, vane, and screw types. Lobe and progressive cavity are typically not offered with mag-drive due to design limitations.

What to consider for selecting appropriate mag-drive PD rotary pumps:

- Viscosity: Can be used for both thin and thick liquids. For thicker liquids, one needs to be mindful of torque rating on the magnetic coupling. Insufficient torque rating of the coupling will result in decoupling of magnets, the pump will stop and, without instrumentation, the drive hub will continue to be rotated by the motor. If the driver is not shut down, overheating and possible coupling damage can occur.

- Pressure: External gear and three-screw pumps are used for higher pressure capabilities. Because the canister is subjected to the pump’s discharge pressure, it must be strong enough to prevent distortion or bursting at high pressures.

- Abrasives: Typically internal gear pumps are used for such applications. Many mag-drive design have hollow shaft for recirculating the liquid, and one needs to consider the nature of mixture (suspended or non-suspended solids) to avoid blockage of the hollow shaft.

- Temperature: Even at ambient temperature liquids, heat generated by eddy current from the mag-drive can be a concern, especially for flammable liquids or temperature sensitive resins. One should consider both a canister temperature sensor and power load monitor to ensure that overheating hue to eddy currents or dry run situations don’t occur.

With increase in temperature, the torque rating of magnets goes down. Different types of magnets have different temperature ratings. Standard is Neodymium magnets, offering the lowest cost and highest torque, but are limited to about 108-deg C. Samarium cobalt magnets must be used for higher temperatures, but are still limited to about 260-deg C. For liquids that solidify at room temperatures (for example coal tar pitch) some manufacturers offer jacketing for steam or hot oil to allow pump to be heated before start up.

With increased uses of mag-drive pumps, the initial costs have reduced considerably. Mostly, cost of mag-drive pump is lower than that of pumps with double or tandem seal with seal plans. Moreover, when you consider the total life cycle cost (LCC) of the pumps, pump users will save significantly by using mag-drive pumps over conventional sealed pumps.

References:

1. Mag Drive Rotary PD Process Pumps, by John Halls

Source: Pumps & Systems Magazine

Link: http://www.pump-zone.com/topics/pumps/rotary-pumps/mag-drive-rotary-pd-process-pumps

2. Understanding and Using Sealless Rotary Pumps

Source: Colfax® Website

Link: http://www.colfaxcorp.com/admin/modules/page_editor/uploads/file/6870-SeallessRotaryPumps_3.pdf

3. Pump Technology Details from Micropump®

Link: http://www.micropump.com/technology_pump_technology.aspx

4. Mag Drive pumps from Viking® Pump

Link: http://vikingpump.com/en/products/pumps/internal_gear/magDrive.html